European Union Law: End-of-Life Vehicles

EU rules aim to make the dismantling and recycling of end-of-life vehicles more environmentally friendly.

The Directive on end-of-life vehicles (ELV Directive) set clear targets for ELVs and their components. It also prohibits the use of hazardous substances when manufacturing new vehicles (especially lead, mercury, cadmium and hexavalent chromium) except in defined exemptions when there are no adequate alternatives. The exemptions are listed in annex II of the Directive.

Source: End-of-Life Vehicles, European Commision, Environment

Extract from the directive

“Member States shall ensure that materials and components of vehicles put on the market after 1 July 2003 do not contain lead, mercury, cadmium or hexavalent chromium other than in cases listed in Annex II under the conditions specified therein;”

“A maximum concentration value up to 0,1 % by weight in homogeneous material for lead, hexavalent chromium and mercury and up to 0,01 % by weight in homogeneous material for cadmium shall be tolerated.”

Zinc-Nickel plating : providing corrosion resistance and protection from galvanic corrosion

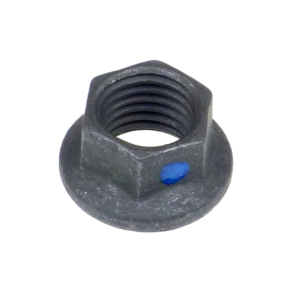

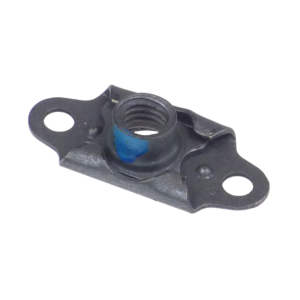

In the past 20 years many studies on different plating methods have been carried out by both the automotive and aerospace industries. Zinc-Nickel plating is now seen as the preferred alternative to the toxic cadmium plating and an improvement over traditional zinc plating. Zinc-Nickel plating, free of both cadmium and hexavalent chrome VI, has been selected as the environmental friendly finish for the BlueFast® range of hexagonal k-nuts and floating anchor nuts.

Zinc-Nickel plating has been widely used in the automotive industry for over 20 years and offers the following advantages:

- Zinc-Nickel plating provides greater resistance to corrosion when compared to zinc plating, salt spray test results have shown up to 4 times greater.

- Zinc-Nickel plating reduces the risk of galvanic corrosion when using dissimilar materials.

BlueFast® k-nuts and anchor nuts are used in high performance applications and not only meet the ELV Directive but also provide designers with an environment friendly value added fastener solution.

BlueFast® Technical: Performance and Engineering support

Performance 3 Crimp Locking

3 crimp locking deformation is applied across the BlueFast® range of hexagonal k-nuts to ensure consistent locking performance on many different types of bolt and stud. To achieve this, and guarantee repeat performance, the locking torque is controlled and recorded for 15 cycles of each production batch.

The locking torque and performance of the BlueFast® range meet the LN65016 standard.

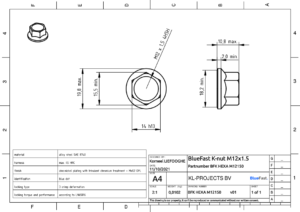

Technical drawings, 3D models & MDS entries

To offer a comprehensive support package for designers we have available, on request, technical drawings and 3D CAD models for fast integration into your design.

The automotive industry specifically requires the entry of each product in the MDS database in order to know and control all materials and substances in the end product.

To receive the information required please complete the form below.

Contact us

"*" indicates required fields